Graphite accessories for single crystal furnaces in the photovoltaic industry play a vital role in solar cell manufacturing. They directly affect the production efficiency and quality of solar cells by providing a stable thermal environment and supporting the growth of silicon single crystals. Therefore, research and development and innovation are continuously carried out to improve the performance, durability and adaptability of graphite accessories to meet the needs of the evolving photovoltaic industry.

Introduction:

1. Material selection: The graphite accessories for the thermal field of the single crystal furnace in the photovoltaic industry usually use high-purity graphite materials. These graphite accessories need to have high purity, low impurity content and excellent thermal conductivity to ensure the stability of the thermal field and durability in high temperature environments.

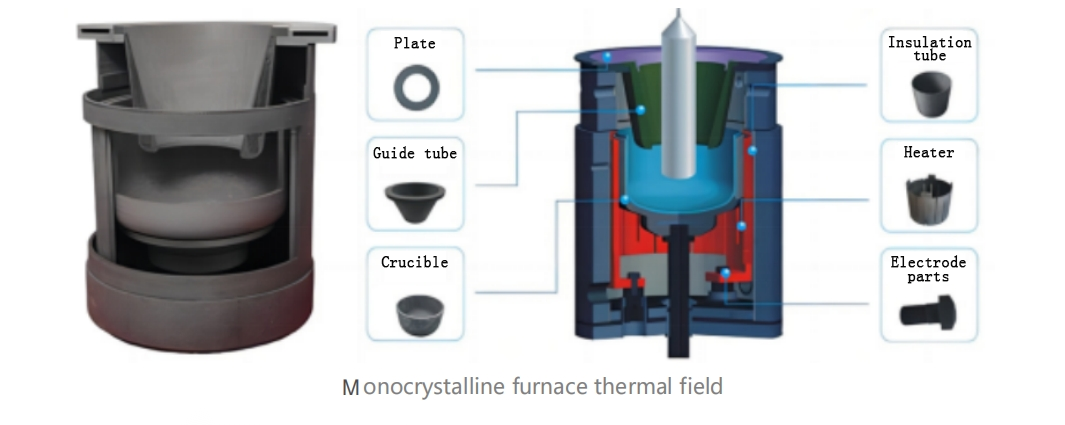

2. Thermal field design: The design of the graphite accessories for the thermal field of the single crystal furnace needs to consider the uniformity and stability of the thermal field. The shape and structure of the graphite accessories play an important role in the conduction and distribution of the thermal field to ensure that the silicon single crystal is heated evenly in the furnace and obtains a consistent temperature distribution.

3. Thermal conductivity: The graphite accessories for the thermal field of the single crystal furnace in the photovoltaic industry need to have good thermal conductivity to provide efficient thermal conduction and uniform temperature distribution. This helps to ensure that the silicon single crystal is heated evenly throughout the growth process in the furnace and reduce the impact of temperature gradients on crystal quality.

4. High temperature resistance: Since the growth temperature in the single crystal furnace is usually high, the graphite accessories for the thermal field of the single crystal furnace in the photovoltaic industry need to have good high temperature resistance. They should be able to maintain structural stability and mechanical strength in a high temperature environment to ensure long-term stable operation.

5. Corrosion resistance: The graphite accessories for the thermal field of the single crystal furnace in the photovoltaic industry also need to have good corrosion resistance to cope with the chemical reactions that may occur when in contact with silicon materials and other chemicals. This helps to maintain the stability and life of the graphite accessories.