Silicon Carbide (SiC) Furnace Tubes: Advanced Solution for the Photovoltaic and Semiconductor Industries

Silicon carbide (SiC) furnace tubes are critical components in the photovoltaic and semiconductor industries. Traditional quartz furnace tubes are effective up to 800°C, but when used in oxidation diffusion processes that exceed 1000°C, their lifespan dramatically decreases. This results in stress, deformation, and contamination of the wafers due to impurities leaching from the quartz tube.

In contrast, SiC furnace tubes provide superior performance and longevity, with numerous benefits:

Key Advantages of Silicon Carbide Furnace Tubes

-Exceptional High-Temperature Stability: SiC furnace tubes can withstand temperatures up to 1700°C in air, and up to 1950°C in inert gases like nitrogen or argon, far outlasting quartz tubes in high-temperature applications.

-Superior Thermal Expansion Performance: SiC has a thermal expansion coefficient that closely matches that of amorphous silicon, significantly reducing the risk of cracking or breakage due to thermal expansion, which is common with quartz tubes.

-High Purity Materials: Semicera offers SiC tubes with 99.99% purity, coupled with CVD SiC coatings with 99.99998% purity. This ensures wafer protection from impurities, eliminating contamination issues during high-temperature processes.

-Outstanding Corrosion and Wear Resistance: SiC tubes exhibit excellent resistance to corrosion and wear under high temperatures, preventing potential contamination and degradation often associated with quartz tubes.

-Excellent Thermal Shock Resistance: With high thermal conductivity and remarkable thermal shock resistance, SiC furnace tubes can handle rapid temperature changes, making them highly durable in dynamic industrial processes.

Applications

Semicera’s SiC furnace tubes are widely used as replacements for quartz tubes in vertical oxidation furnaces, diffusion furnaces, and RTP equipment. Our products have been successfully operating in multiple client facilities since 2018, demonstrating their exceptional performance and reliability.

Additionally, Semicera provides matching high-purity SiC products including SiC boats, SiC tubes, SiC paddles, and CVD SiC coatings to meet the diverse needs of high-temperature processes.

Why Choose Semicera SiC Furnace Tubes?

-Longer lifespan and better performance in extreme conditions compared to quartz furnace tubes.

-Reduced impurity contamination due to high purity materials.

-High thermal stability, even under fluctuating temperatures.

-Reliable and proven performance in industries such as semiconductor manufacturing and photovoltaic production.

Choose Semicera’s SiC furnace tubes for enhanced durability, reduced maintenance, and superior results in your high-temperature applications.

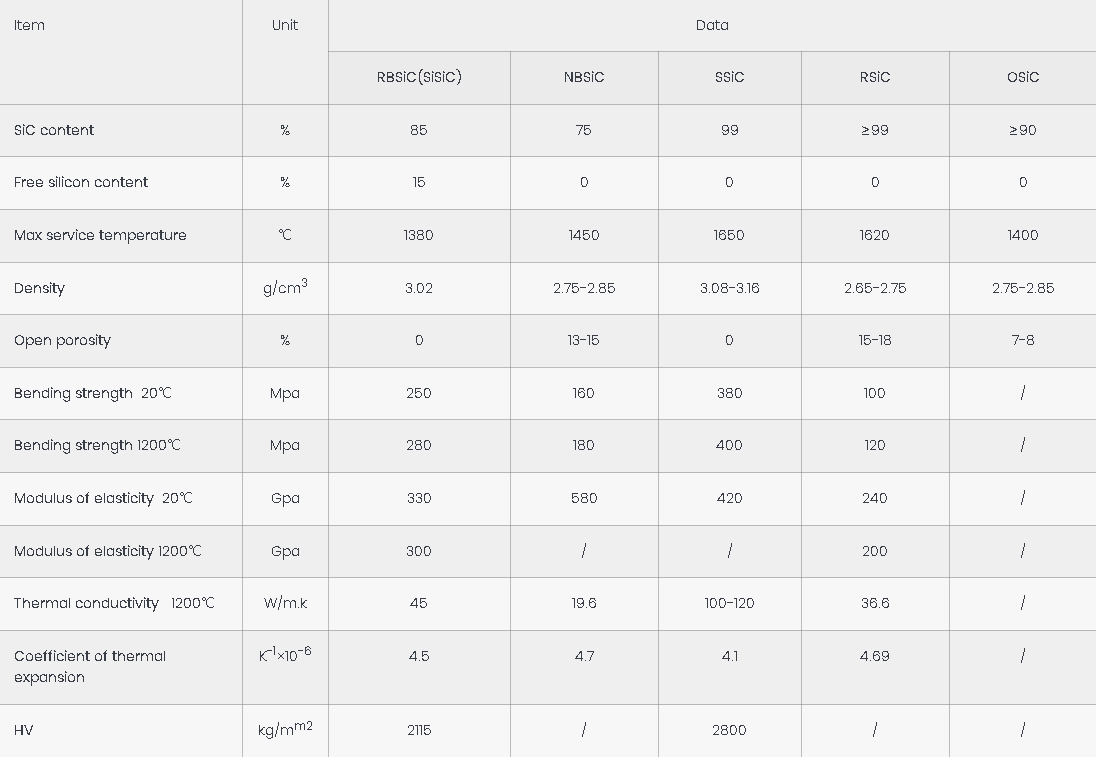

Technical Parameters