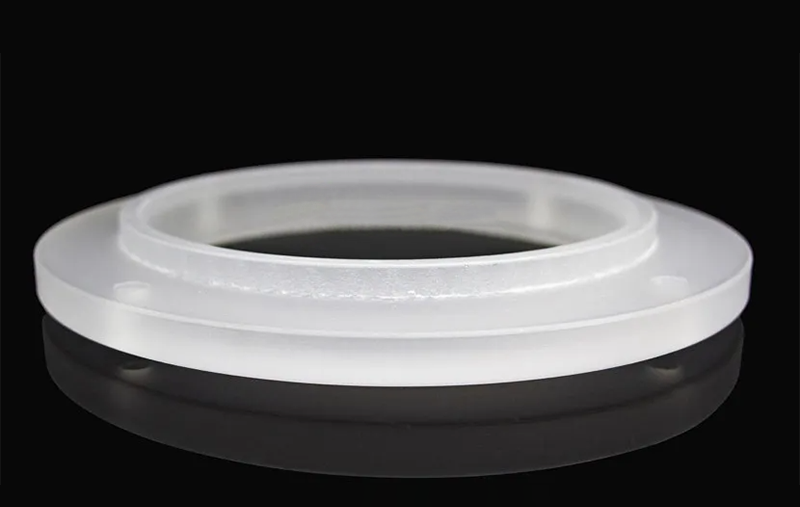

Fused Quartz Ring from semicera is engineered for high-performance applications in semiconductor and industrial processes. Known for its exceptional purity and thermal stability, the Fused Quartz Ring is an essential component in various high-temperature environments. Semicera ensures that each ring meets stringent quality standards, making it ideal for use in Quartz Boat, Quartz Tube, and Quartz Crucible applications.

The versatility of the Fused Quartz Ring extends to its integration within Quartz Tank and Quartz Pedestal setups. These rings provide a reliable solution for maintaining optimal conditions during processing, ensuring minimal contamination and maximum efficiency. As part of our extensive product line, including Quartz Bell Jar and other quartz parts, semicera is committed to delivering superior products tailored to meet the specific needs of our clients.

In addition to their structural integrity, Fused Quartz Rings offer excellent chemical resistance, making them suitable for a wide range of applications. Whether you're working in semiconductor manufacturing, chemical processing, or laboratory environments, these rings provide the durability and reliability necessary for success.

By choosing semicera for your Fused Quartz Ring needs, you benefit from our expertise in quartz technology and our commitment to delivering high-quality products. Our focus on customer satisfaction ensures that you receive solutions that enhance your operational efficiency while maintaining the highest standards of purity and performance.

Advantages of Semicorex Fused Quartz Ring

1. Exceptional Purity

The purity of SiO2 in the Fused Quartz Ring is one of its most significant advantages. With purity levels ranging from 99.995% to 99.999%, the Fused Quartz Ring ensures minimal contamination and high-quality etching results. This high purity is crucial in semiconductor manufacturing, where even the smallest impurities can affect the performance and reliability of the final product.

2. Superior Thermal Stability

The Fused Quartz Ring is designed to withstand extreme temperatures, with an operating temperature of up to 1250°C and a softening temperature of 1730°C. This high thermal stability allows the Fused Quartz Ring to maintain its structural integrity and performance under the intense heat conditions commonly encountered in the etching process.

3. Low Coefficient of Expansion

The extremely low coefficient of expansion of the Fused Quartz Ring makes it highly resistant to thermal shock. This property is crucial in the etching process, where rapid temperature changes can occur. The low coefficient of expansion ensures that the Fused Quartz Ring remains stable and reliable, reducing the risk of cracking and other thermal stress-related issues.

4. Chemical Resistance

The Fused Quartz Ring exhibit excellent resistance to acids and alkalis. This chemical resistance ensures that the Fused Quartz Ring can withstand the harsh conditions of the etching process, maintaining their performance and durability over extended periods.

5. Micro Bubble Free and Low Hydroxyl Content

The absence of micro bubbles and low hydroxyl content in the Fused Quartz Ring ensures that they provide consistent and reliable performance. Micro bubbles and high hydroxyl content can lead to defects and contamination in the etching process, affecting the quality and reliability of the final product.

6. Low Thermal Conductivity and Dielectric Constant

The Fused Quartz Ring has very low thermal conductivity and dielectric constant, as well as the lowest loss tangent of almost all known materials. The low thermal conductivity helps to dissipate heat effectively, reducing the risk of thermal damage to the wafer. The low dielectric constant and loss tangent ensure that our quartz rings provide excellent electrical insulation, reducing the risk of electrical interference and improving the overall efficiency of the etching process.