Well-run tools, skilled gross sales team, and improved after-sales companies; We’re also a unified huge family members, absolutely everyone stick to the organization benefit “unification, devotion, tolerance” for Fixed Competitive Price Customized Reaction Sintering Silicon Carbide Sic Ceramic Cone Nozzles for Industrial Desulfurating, If you’re interested in any of our merchandise or wish to talk about a tailored buy, you should really feel totally free to get hold of us.

Well-run tools, skilled gross sales team, and improved after-sales companies; We’re also a unified huge family members, absolutely everyone stick to the organization benefit “unification, devotion, tolerance” for China Silicon Carbide Ceramic Sand Blasting Nozzle and Rbsic Burner Nozzles, In order to make more people know our items and to enlarge our market, we’ve got devoted a lot of attention to technical innovations and improvement, as well as replacement of equipment. Last but not the least, we also pay more attention to training our managerial personnel, technicians and workers in planned way.

Silicon carbide is a new type of ceramics with high cost performance and excellent material properties. Due to features like high strength and hardness, high temperature resistance, great thermal conductivity and chemical corrosion resistance, Silicon Carbide can almost withstand all chemical medium. Therefore, SiC are widely used in oil mining, chemical, machinery and airspace, even nuclear energy and the military have their special demands on SIC. Some normal application we can offer are seal rings for pump, valve and protective armor etc.

We are able to design and manufacture according to your specific dimensions with good quality and reasonable deliver time.

![]()

Applications:

-Wear-resistant Field: bushing, plate, sandblasting nozzle,cyclone lining, grinding barrel,etc…

-High Temperature Field: siC Slab, Quenching Furnace Tube,Radiant Tube,crucible,Heating Element, Roller, Beam, Heat Exchanger, Cold Air Pipe, Burner Nozzle, Thermocouple Protection Tube, SiC boat,Kiln car Structure,Setter,etc.

-Military Bulletproof Field

-Silicon Carbide Semiconductor: SiC wafer boat, sic chuck,sic paddle, sic cassette, sic diffusion tube, wafer fork, suction plate, guideway,etc.

-Silicon Carbide Seal Field: all kinds of sealing ring, bearing, bushing, etc.

-Photovoltaic Field: Cantilever Paddle, Grinding Barrel, Silicon Carbide Roller,etc.

-Lithium Battery Field

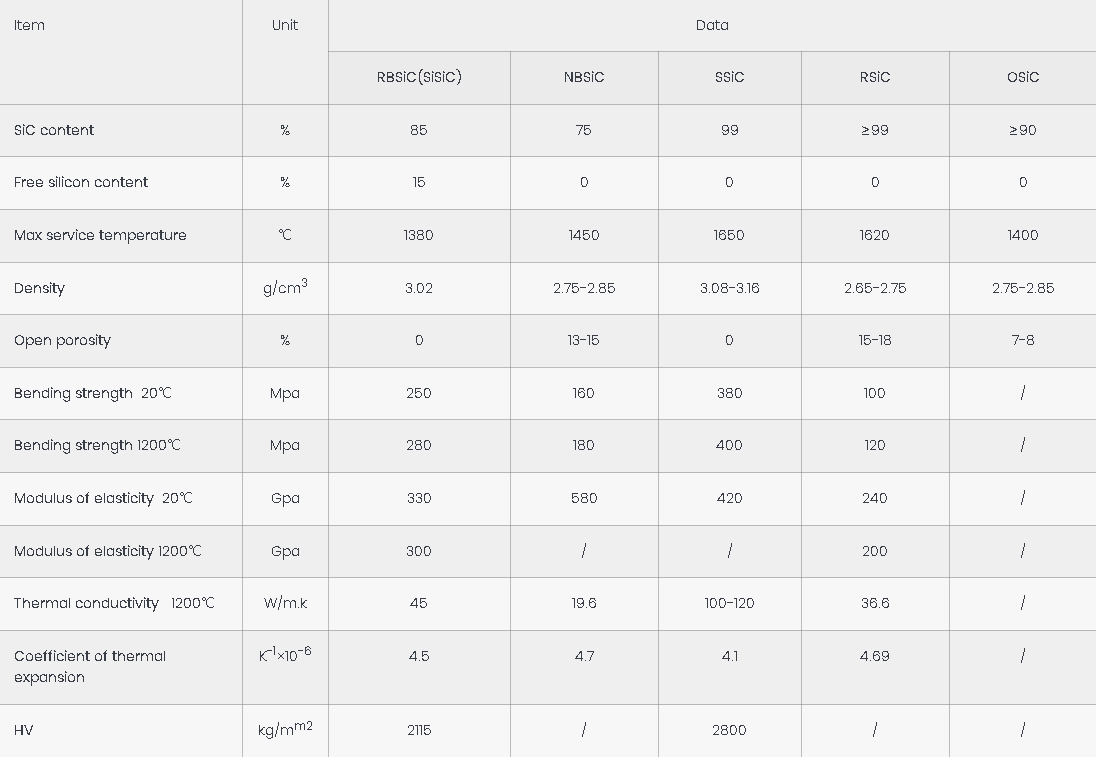

Technical Parameters

Well-run tools, skilled gross sales team, and improved after-sales companies; We’re also a unified huge family members, absolutely everyone stick to the organization benefit “unification, devotion, tolerance” for Fixed Competitive Price Customized Reaction Sintering Silicon Carbide Sic Ceramic Cone Nozzles for Industrial Desulfurating, If you’re interested in any of our merchandise or wish to talk about a tailored buy, you should really feel totally free to get hold of us.

Fixed Competitive Price China Silicon Carbide Ceramic Sand Blasting Nozzle and Rbsic Burner Nozzles, In order to make more people know our items and to enlarge our market, we’ve got devoted a lot of attention to technical innovations and improvement, as well as replacement of equipment. Last but not the least, we also pay more attention to training our managerial personnel, technicians and workers in planned way.

-

Factory Promotional Heat Preservation Soft Carb...

-

Factory Cheap Customized/OEM Stainless Steel El...

-

Good Quality 50% Wool 50% Synthetic Soft Needle...

-

Professional Factory for China Supplier Silicon...

-

Best-Selling Soft for Heat Carbon Rigid Felts M...

-

OEM Factory for Customizable High Temperature a...