We insist on the principle of development of ‘High quality, Efficiency, Sincerity and Down-to-earth working approach’ to provide you with excellent service of processing for Factory Free sample Customized High Temperature Resistance Sic Pipe Silicon Carbide Ceramic Tube for Kiln Furnace, Any interest, remember to really feel absolutely free to make contact with us. We’re hunting forward to forming prosperous small business relationships with new consumers within the environment while in the in the vicinity of long term.

We insist on the principle of development of ‘High quality, Efficiency, Sincerity and Down-to-earth working approach’ to provide you with excellent service of processing for China Refractory Ceramic Tube and Sic Pipe, We always stick to the tenet of “sincerity, high quality, high efficiency, innovation”. With years of efforts, now we have established friendly and stable business relationships with worldwide customers. We welcome any of your inquiries and concerns for our solutions, and we have been sure that we will offer you just what you want, as we always believe that your satisfaction is our success.

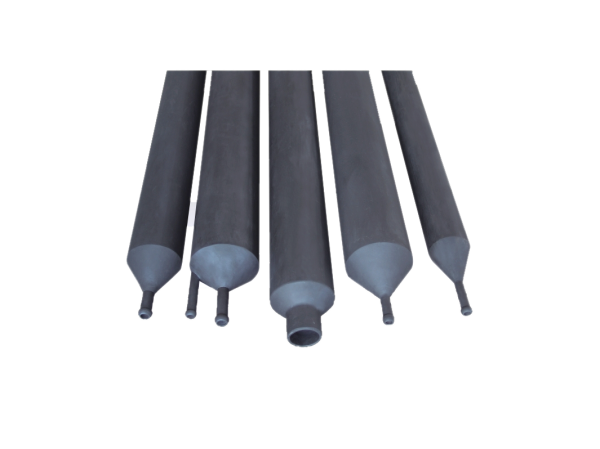

We can provide stable and reliable silicon carbide crystal boats, silicon carbide paddles, silicon carbide furnace tubes for the 4 inch to 6 inch semiconductor wafer industry. The purity can reach 99.9% without polluting the wafer.

Silicon carbide furnace tube is mainly used for: 4-6 inch silicon wafer LTO= silica, SIPOS= oxy-polysilicon, SI3N4= silicon nitride, PSG= phosphosilicon glass, POLY= polysilicon film growth. It is the raw material gas (or liquid source gasification) activated by thermal energy to generate a solid film on the surface of the substrate. Low pressure chemical vapor deposition is carried out at low pressure, due to the low pressure, the average free path of gas molecules is large, so that the uniformity of the grown film is good, and the substrate can be vertically placed and the amount of loading is large, especially suitable for large-scale integrated circuits, discrete devices, power electronics, optoelectronic devices and optical fiber and other industries of industrial production special equipment.

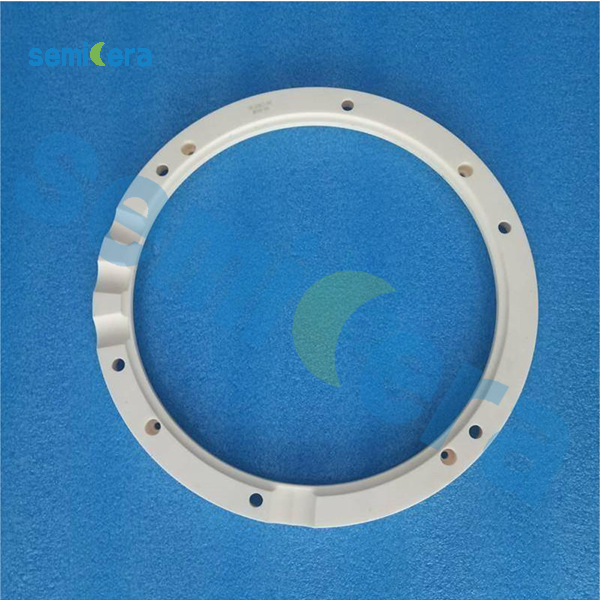

Semicera Energy Technology Co., Ltd is a professional research, development, production and sales of silicon carbide ceramic products. Since its establishment in 2016, Semicera Energy has mastered isostatic pressing molding process, thousand pressing molding process, grouting molding process and vacuum extrusion molding process. Our company uses 6 silicon carbide ceramic sintering production lines, has 8 CNC, 6 precision grinding machines, can also provide you with silicon carbide ceramic sintered products, but also can provide silicon carbide ceramics, alumina ceramics, aluminum nitride ceramics, zirconia ceramics processing services.

We insist on the principle of development of ‘High quality, Efficiency, Sincerity and Down-to-earth working approach’ to provide you with excellent service of processing for Factory Free sample Customized High Temperature Resistance Sic Pipe Silicon Carbide Ceramic Tube for Kiln Furnace, Any interest, remember to really feel absolutely free to make contact with us. We’re hunting forward to forming prosperous small business relationships with new consumers within the environment while in the in the vicinity of long term.

Factory Free sample China Refractory Ceramic Tube and Sic Pipe, We always stick to the tenet of “sincerity, high quality, high efficiency, innovation”. With years of efforts, now we have established friendly and stable business relationships with worldwide customers. We welcome any of your inquiries and concerns for our solutions, and we have been sure that we will offer you just what you want, as we always believe that your satisfaction is our success.

-

China wholesale Silicon Carbide Sic Cantilever ...

-

OEM/ODM China High Temperature Insulation 95%99...

-

Top Suppliers Silicon Carbide Sic Rod Heating E...

-

High definition Refractory Silicon Carbide Cant...

-

Good quality Heat Resistance Carbon Felt / Soft...

-

OEM Supply Certification Silicon Carbide Sic Ca...