Epitaxy Wafer Carrier is a critical component in semiconductor production, especially in Si Epitaxy and SiC Epitaxy processes. Semicera carefully designs and manufactures Wafer Carriers to withstand extremely high temperatures and chemical environments, ensuring excellent performance in applications such as MOCVD Susceptor and Barrel Susceptor. Whether it is the deposition of monocrystalline silicon or complex epitaxy processes, Semicera's Epitaxy Wafer Carrier provides excellent uniformity and stability.

Semicera's Epitaxy Wafer Carrier is made of advanced materials with excellent mechanical strength and thermal conductivity, which can effectively reduce losses and instability during the process. In addition, the design of the Wafer Carrier can also adapt to epitaxy equipment of different sizes, thereby improving overall production efficiency.

For customers who require high-precision and high-purity epitaxy processes, Semicera's Epitaxy Wafer Carrier is a trustworthy choice. We are always committed to providing customers with excellent product quality and reliable technical support to help improve the reliability and efficiency of production processes.

✓Top-quality in China market

✓Good service always for you, 7*24 hours

✓Short date of delivery

✓Small MOQ welcome and accepted

✓Custom services

Epitaxy Growth Susceptor

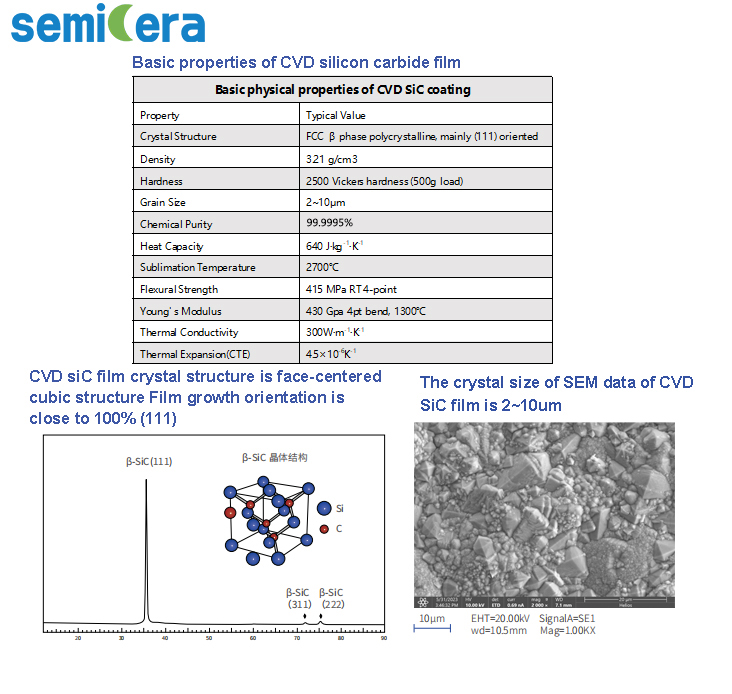

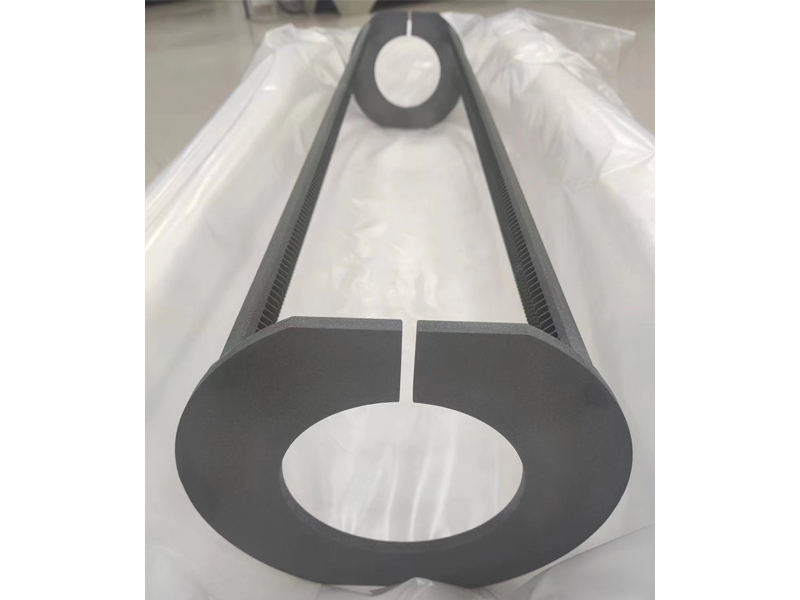

Silicon/silicon carbide wafers need to go through multiple processes to be used in electronic devices. An important process is silicon/sic epitaxy, in which silicon/sic wafers are carried on a graphite base. Special advantages of Semicera's silicon carbide-coated graphite base include extremely high purity, uniform coating, and extremely long service life. They also have high chemical resistance and thermal stability.

LED Chip Production

During the extensive coating of the MOCVD reactor, the planetary base or carrier moves the substrate wafer. The performance of the base material has a great influence on the coating quality, which in turn affects the scrap rate of the chip. Semicera's silicon carbide-coated base increases the manufacturing efficiency of high-quality LED wafers and minimizes wavelength deviation. We also supply additional graphite components for all MOCVD reactors currently in use. We can coat almost any component with a silicon carbide coating, even if the component diameter is up to 1.5M, we can still coat with silicon carbide.

Semiconductor Field, Oxidation Diffusion Process, Etc.

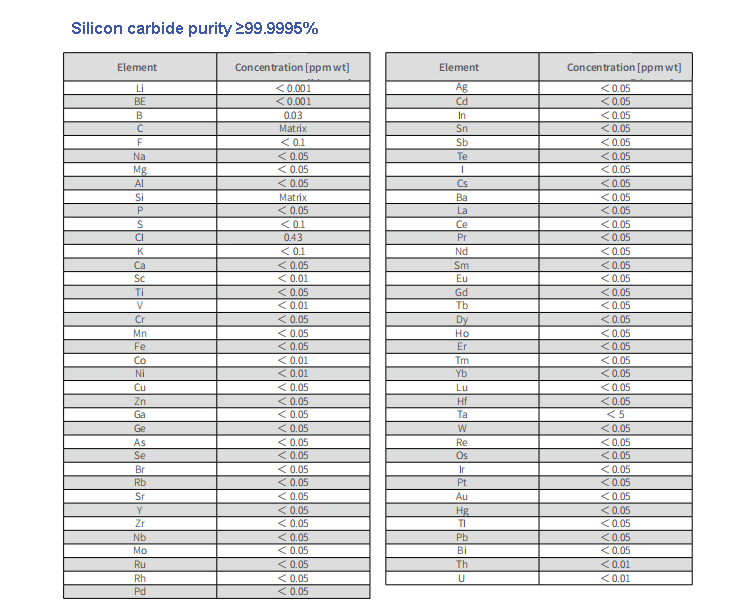

In the semiconductor process, the oxidation expansion process requires high product purity, and at Semicera we offer custom and CVD coating services for the majority of silicon carbide parts.

The following picture shows the rough-processed silicon carbide slurry of Semicea and the silicon carbide furnace tube that is cleaned in the 1000-level dust-free room. Our workers are working before coating. The purity of our silicon carbide can reach 99.98%, and the purity of sic coating is greater than 99.9995%.

Raw Silicon Carbide Paddle and SiC Process Tube in Cleaing

Silicon Carbide Wafer Boat CVD SiC Coated