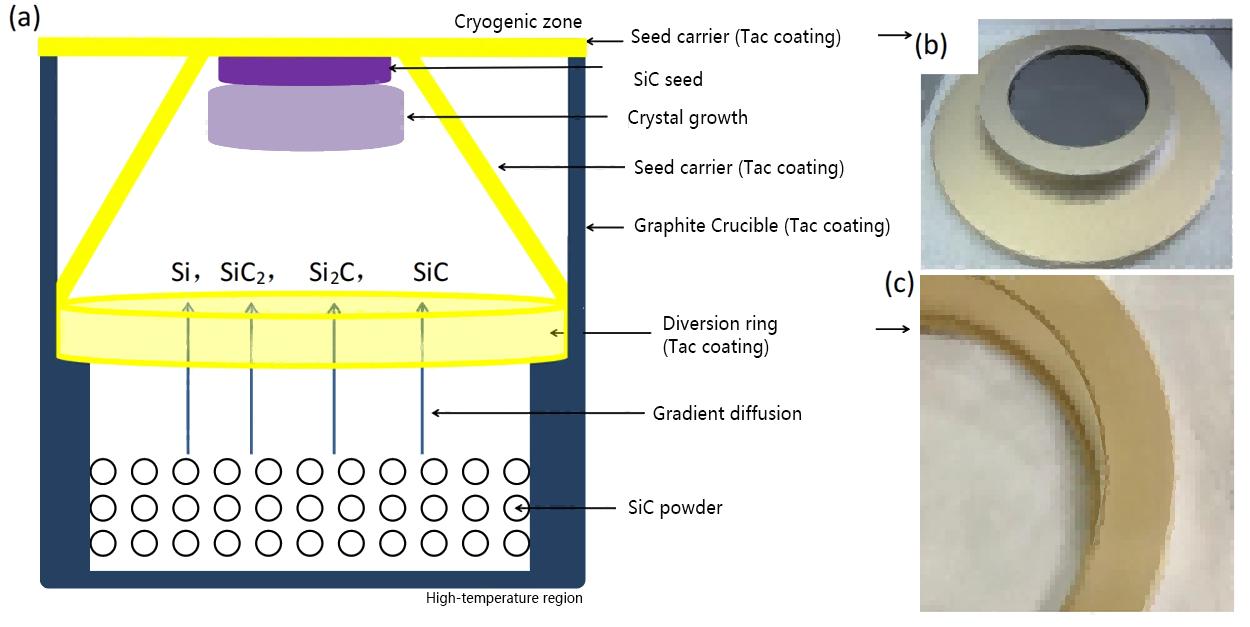

Semicera provides specialized tantalum carbide (TaC) coatings for various components and carriers. Semicera leading coating process enables tantalum carbide (TaC) coatings to achieve high purity, high temperature stability and high chemical tolerance, improving product quality of SIC/GAN crystals and EPI layers (Graphite coated TaC susceptor), and extending the life of key reactor components. The use of tantalum carbide TaC coating is to solve the edge problem and improve the quality of crystal growth, and Semicera has breakthrough solved the tantalum carbide coating technology (CVD), reaching the international advanced level.

Customized tantalum carbide coated rings are ring products that are individually designed and manufactured according to tantalum carbide coating technology based on the specific needs and application requirements of customers.

The following is a general description of customized tantalum carbide coated rings:

1. Material selection: According to customer needs, high-purity tantalum materials are selected as the substrate to ensure the quality and performance of the product.

2. Size and shape: According to the requirements or design drawings provided by the customer, the size, diameter, thickness and shape of the tantalum carbide coated ring are customized to adapt to specific application scenarios and equipment requirements.

3. Tantalum carbide coating process: The surface of the tantalum ring is treated using a professional tantalum carbide coating process to form a uniform, dense and well-adhesive tantalum carbide coating.

4. Wear resistance and corrosion resistance: By optimizing the coating process and parameters, ensure that the tantalum carbide coated ring has excellent wear resistance and corrosion resistance to meet the requirements of specific environments.

5. Sealing performance: According to the customer's sealing requirements, the sealing structure of the tantalum carbide coated ring is designed and manufactured to ensure effective sealing performance and prevent gas or liquid leakage.

6. Quality Control: During the customization process, strict quality control and testing are carried out to ensure the consistency, reliability and compliance of the products.

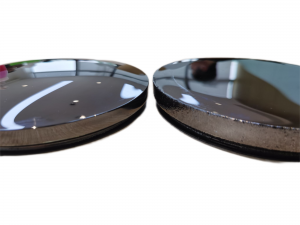

with and without TaC

After using TaC (right)

Moreover, Semicera's TaC-coated products exhibit a longer service life and greater high-temperature resistance compared to SiC coatings. Laboratory measurements have demonstrated that our TaC coatings can consistently perform at temperatures up to 2300 degrees Celsius for extended periods. Below are some examples of our samples: