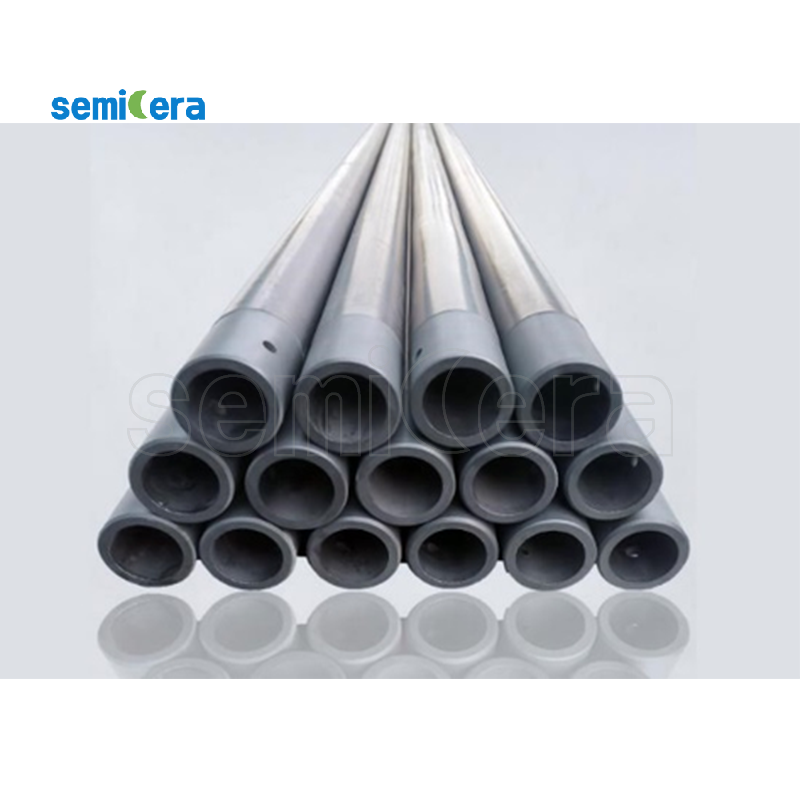

Customized SiC ceramic sleeves are silicon carbide (SiC) ceramic sleeves made according to customer needs. SiC ceramic sleeves are often used to protect and isolate internal components or equipment, providing high temperature stability, corrosion resistance, and wear resistance.

Customized silicon carbide ceramic sleeves are widely used in many applications, such as high-temperature furnaces, heat treatment equipment, chemical reactors, pump systems, sensors and valves. They provide excellent protection and isolation performance in these applications, while being able to withstand harsh environmental conditions such as high temperature, chemical corrosion and wear.

Can be customized according to requirements;

Can make very complex structures;

The surface can be polished;

It can be used at 1400 ℃;

High hardness, very wear-resistant;

High corrosion resistance;

Features of customized SiC ceramic sleeves include:

1. Material selection: SiC materials of different purity and particle size can be selected according to specific application requirements. High-purity SiC materials are often used in applications that require extremely high performance.

2. Size and shape: SiC ceramic sleeves can be customized into various sizes and shapes, including cylindrical, conical, tubular, etc., according to the requirements and designs provided by customers.

3. Surface treatment: SiC ceramic sleeves can be surface treated, such as polishing, grinding, or coating, to improve surface smoothness, reduce friction coefficient, or increase corrosion resistance.

4. Temperature resistance: SiC ceramic sleeves can withstand high temperature environments, have excellent high temperature stability, and withstand high temperatures up to thousands of degrees Celsius.

5. Corrosion resistance: Silicon carbide ceramic sleeves have good corrosion resistance to acids, alkalis and some corrosive media, and can operate stably for a long time in chemical corrosion environments.

6. Wear resistance: Silicon carbide ceramic sleeves have excellent wear resistance and can maintain a long service life under high friction and wiping conditions.