Silicon carbide is a new type of ceramics with high cost performance and excellent material properties. Due to features like high strength and hardness, high temperature resistance, great thermal conductivity and chemical corrosion resistance, Silicon Carbide can almost withstand all chemical medium. Therefore, SiC are widely used in oil mining, chemical, machinery and airspace, even nuclear energy and the military have their special demands on SIC. Some normal application we can offer are seal rings for pump, valve and protective armor etc.

We are able to design and manufacture according to your specific dimensions with good quality and reasonable deliver time.

Non-pressure sintered silicon carbide roller, atmospheric pressure sintered silicon carbide ceramic products, the use of high purity ultra-fine silicon carbide powder, sintered at 2450℃ high temperature, silicon carbide content of more than 99.1%, product density ≥3.10g/cm3, no metal impurities such as metal silicon.

► Silicon carbide content --≥99%;

► High temperature resistance - normal use at 1800℃;

► High thermal conductivity - comparable to the thermal conductivity of graphite materials;

► High hardness - hardness second only to diamond, cubic boron nitride;

► Corrosion resistance - strong acid and alkali do not have any corrosion, corrosion resistance is better than tungsten carbide and alumina;

► Light weight - density 3.10g/cm3, close to aluminum;

► No deformation - very small coefficient of thermal expansion;

► Thermal shock resistance - the material can withstand rapid temperature changes, thermal shock resistance, resistance to cold and heat, stable performance.

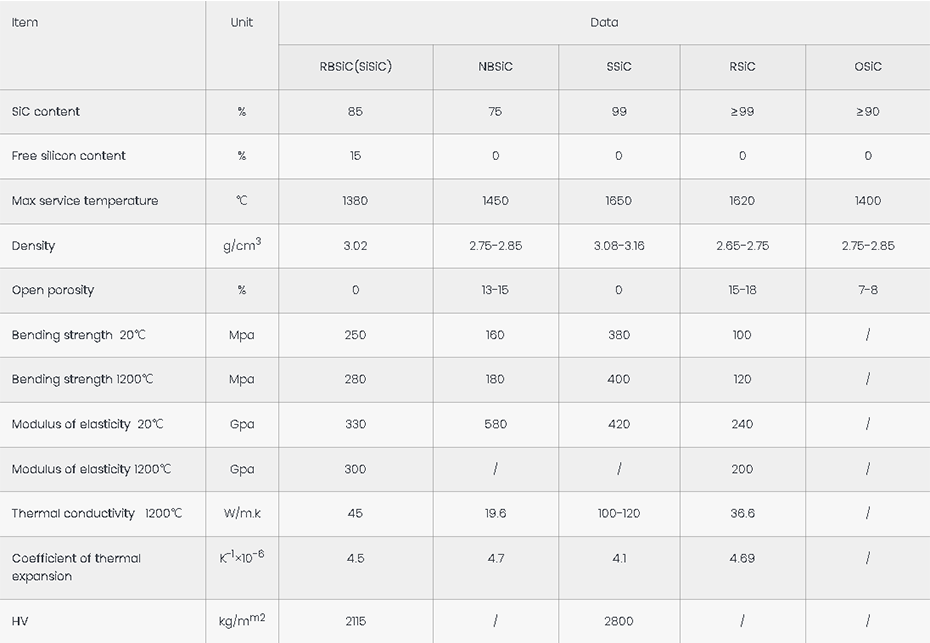

Technical Parameters: