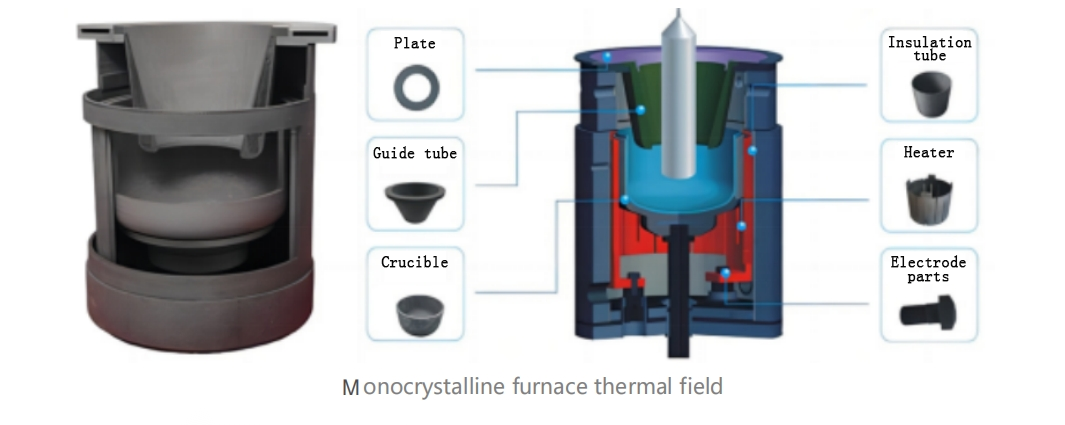

Silicon single crystal crucibles for the photovoltaic industry are key components that support solar cell production. They help achieve efficient silicon single crystal growth by providing a pure and stable melt pool environment, thereby improving the performance and quality of solar cells. Such crucibles are widely used in the photovoltaic industry, and continuous research and development and innovation help to improve the performance and adaptability of crucibles.

Introduction:

1. Material selection: Since the photovoltaic industry has very high requirements for the purity of silicon single crystals, the crucibles for pulling silicon single crystals in the photovoltaic industry usually use high-purity graphite materials. These graphite crucibles need to have extremely high purity and low impurity content to ensure that the produced silicon single crystals have a lower impurity concentration, thereby improving the efficiency of solar cells.

2. Purity control: The purity of the crucibles for pulling silicon single crystals in the photovoltaic industry needs to be strictly controlled during the manufacturing process. Manufacturers usually take a variety of methods, such as high-temperature graphite heat treatment, chemical cleaning and special coatings, to ensure the purity inside the crucible and reduce the presence of impurities.

3. Molten pool shape control: The crucibles for pulling silicon single crystals in the photovoltaic industry need to have good control over the shape of the melt pool. This is to ensure that the silicon material can maintain a stable shape during the melting and growth process, so as to obtain high-quality silicon single crystals. Special crucible designs and bottom shapes may be adopted to achieve the required melt pool shape control.

4. Temperature uniformity: The crucibles for pulling silicon single crystals in the photovoltaic industry need to have good thermal conductivity to ensure uniform temperature distribution inside the crucible. This helps improve the uniformity of silicon single crystals and reduce the formation of impurities and defects.

5. Corrosion resistance and heat resistance: The silicon single crystal crucibles used in the photovoltaic industry need to have good corrosion resistance and heat resistance to withstand the chemical reactions that may occur when in contact with silicon materials at high temperatures. This helps maintain the stability and long-term reliability of the crucible.

-

Solar Graphite Boat for PECVD Solar Cell Produc...

-

Semicera Custom Graphite Solutions for Semicond...

-

Graphite three-petal crucible for semiconductor...

-

Precision-Engineered Graphite Parts by Semicera...

-

Semiceras Customized Isostatic Graphite Compone...

-

High Quality Graphite Heating Elements by Semic...