Our company since its inception, usually regards product high-quality as company life, constantly boost manufacturing technology, boost product excellent and continuously strengthen company total excellent administration, in strict accordance using the national standard ISO 9001:2000 for Cheapest Factory Rigid Graphite Felt for High Pressure Sinter Furnaces, Currently, we’re seeking ahead to even bigger cooperation with abroad customers according to mutual gains. Please experience free of charge to get in touch with us for more specifics.

Our company since its inception, usually regards product high-quality as company life, constantly boost manufacturing technology, boost product excellent and continuously strengthen company total excellent administration, in strict accordance using the national standard ISO 9001:2000 for China Graphite Felt and Rigid Felt, During the short years, we serve our clients honestly as Quality First, Integrity Prime, Delivery Timely, which has earned us an outstanding reputation and an impressive client care portfolio. Looking forward to working with you Now!

Product details

|

Product name |

Graphite Felt |

|

Chemical Composition |

Carbon fiber |

|

Bulk density |

0.12-0.14g/cm3 |

|

Carbon content |

>=99% |

|

Tensile Strength |

0.14Mpa |

|

Thermal conductivity(1150℃) |

0.08~0.14W/mk |

|

Ash |

<=0.005% |

|

Crushing stress |

8-10N/cm |

|

Thickness |

1-10mm |

|

Processing temperature |

2500(℃) |

Volume Density (g/cm3): 0.22-0.28

Tensile Strength (Mpa): 2.5 (Deformation 5%)

Thermal Conductivity (W/m.k): 0.15-0.25(25) 0.40-0.45(1400)

Specific Resistance (Ohm.cm): 0.18-0.22

Carbon Content (%): ≥99

Ash Content (%): ≤0.6

Moisture Absorption (%): ≤1.6

Purification Scale : Hight Purity

Processing Temperature : 1450-2000

There are currently four grades available to provide raw or processed products:

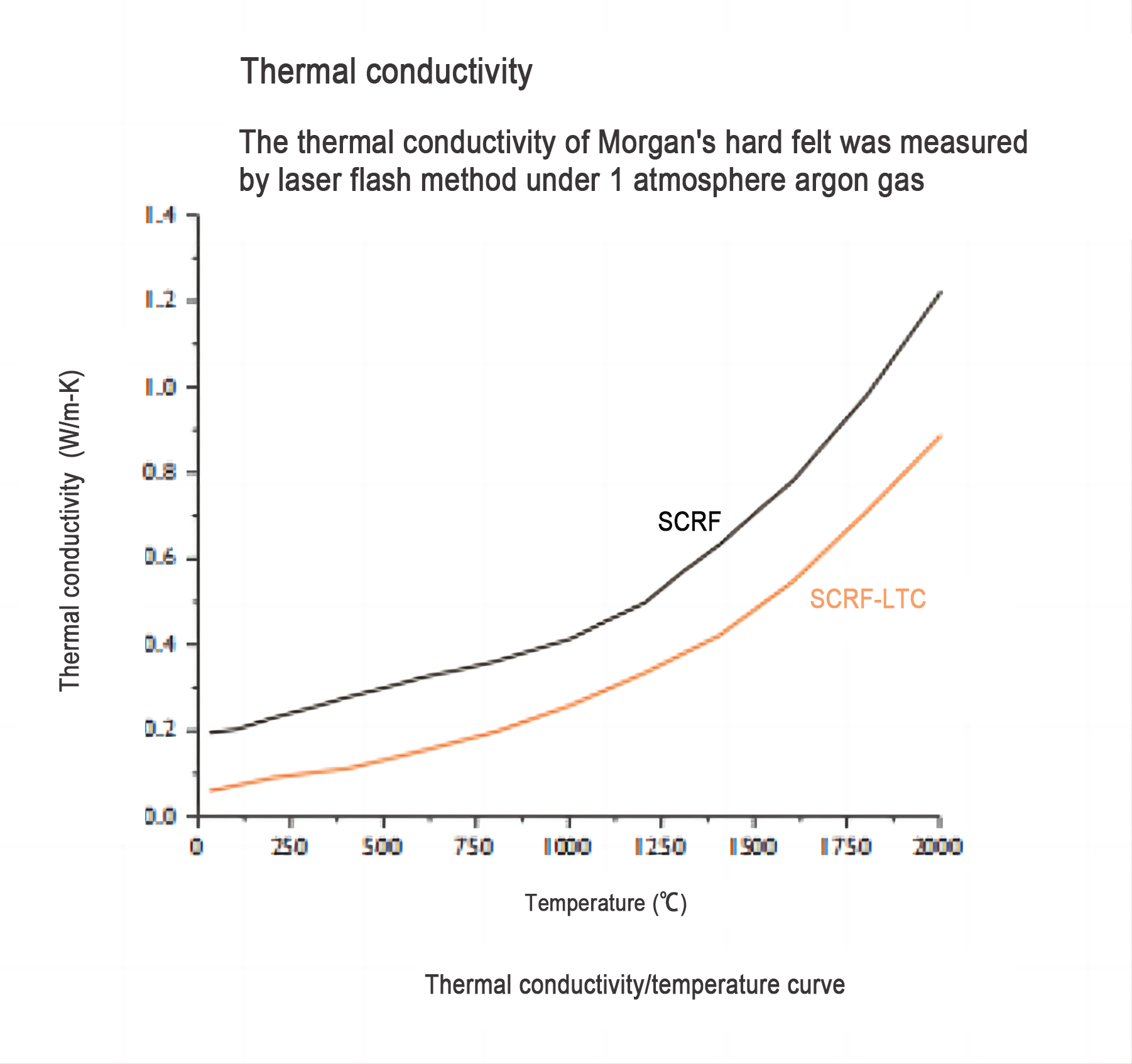

SCRF: Purified cured graphite fiber hard felt, heat treatment temperature above 1900℃

SCRF-P: Highly purified RGB hard felt

SCRF-LTC: Purified solidified graphite fiber hard felt, heat treatment temperature above 1900℃, with better thermal insulation performance

SCRF-LTC-P: Highly purified RGB-LTC hard felt

Available Size:

Plate: 1500*1800(Max) Thickness 20-200mm

Round Drum: 1500*2000(Max) Thicknes 20-150mm

Square Drum: 1500*1500*2000(Max) Thickness 60-120mm

Applicative Temperature Range : 1250-2600

Fields of applications:

•Vacuum furnaces

•Inert gas furnaces

•Heat treatment (hardening, carbonization, brazing, etc.)

•Carbon fiber production

•Hard metal production

•Sintering applications

•Technical ceramic production

•CVD/PVD coasting

Our company since its inception, usually regards product high-quality as company life, constantly boost manufacturing technology, boost product excellent and continuously strengthen company total excellent administration, in strict accordance using the national standard ISO 9001:2000 for Cheapest Factory Rigid Graphite Felt for High Pressure Sinter Furnaces, Currently, we’re seeking ahead to even bigger cooperation with abroad customers according to mutual gains. Please experience free of charge to get in touch with us for more specifics.

Cheapest Factory China Graphite Felt and Rigid Felt, During the short years, we serve our clients honestly as Quality First, Integrity Prime, Delivery Timely, which has earned us an outstanding reputation and an impressive client care portfolio. Looking forward to working with you Now!

-

Rapid Delivery for China Supplier Silicon Carbi...

-

High definition Refractory Silicon Carbide Cant...

-

China Cheap price 1mm Wall Thickness Silicon Ca...

-

Manufacturer for SiSiC/RBSIC Silicon Carbide C...

-

High Performance High Working Temperature Refra...

-

Original Factory Refining Metal Graphite Silico...