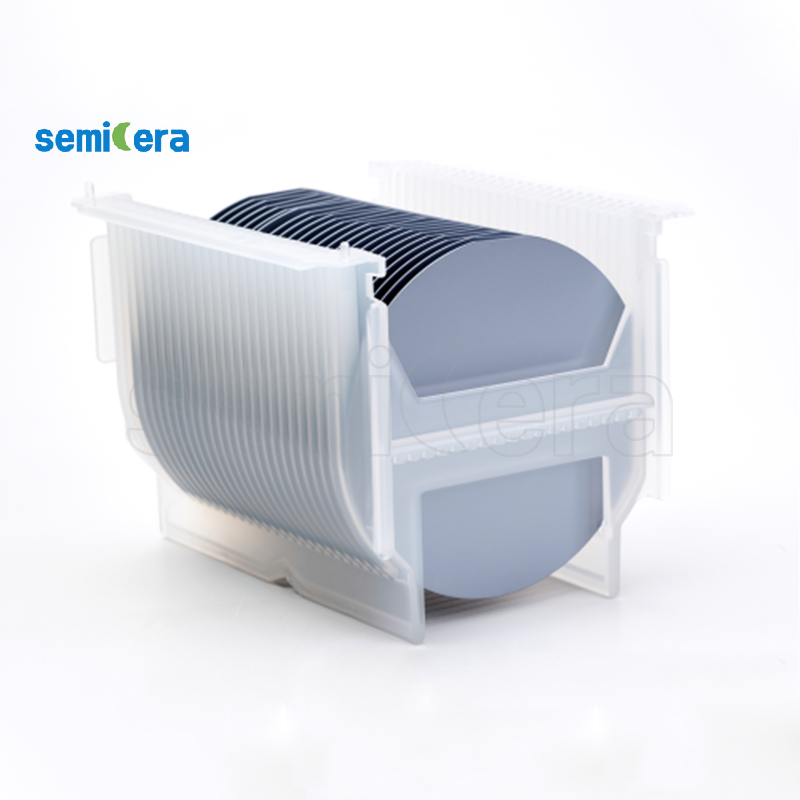

Semicera’s 6-inch LiNbO3 Bonding Wafer is engineered to meet the rigorous standards of the semiconductor industry, delivering unparalleled performance in both research and production environments. Whether for high-end optoelectronics, MEMS, or advanced semiconductor packaging, this bonding wafer offers the reliability and durability necessary for cutting-edge technology development.

In the semiconductor industry, the 6-inch LiNbO3 Bonding Wafer is widely used for bonding thin layers in optoelectronic devices, sensors, and microelectromechanical systems (MEMS). Its exceptional properties make it a valuable component for applications requiring precise layer integration, such as in the fabrication of integrated circuits (ICs) and photonic devices. The high purity of the wafer ensures that the final product maintains optimal performance, minimizing the risk of contamination that could affect device reliability.

| Thermal and electrical properties of LiNbO3 | |

| Melting point | 1250 ℃ |

| Curie temperature | 1140 ℃ |

| Thermal conductivity | 38 W/m/K @ 25 ℃ |

| Coefficient of thermal expansion (@ 25°C) |

//a,2.0×10-6 /K //c,2.2×10-6 /K |

| Resistivity | 2×10-6 Ω·cm @ 200 ℃ |

| Dielectric constant |

εS11/ε0=43,εT11/ε0=78 εS33/ε0=28,εT33/ε0= 2 |

| Piezoelectric constant |

D22=2.04×10-11 C/N D33=19.22×10-11 C/N |

| Electro-optic coefficient |

γT33=32 pm/V, γS33=31 pm/V, γT31=10 pm/V, γS31=8.6 pm/V, γT22=6.8 pm/V, γS22=3.4 pm/V, |

|

Half-wave voltage, DC |

3.03 KV 4.02 KV |

The 6-inch LiNbO3 Bonding Wafer from Semicera is specifically designed for advanced applications in the semiconductor and optoelectronics industries. Known for its superior wear resistance, high thermal stability, and exceptional purity, this bonding wafer is ideal for high-performance semiconductor manufacturing, offering long-lasting reliability and precision even in demanding conditions.

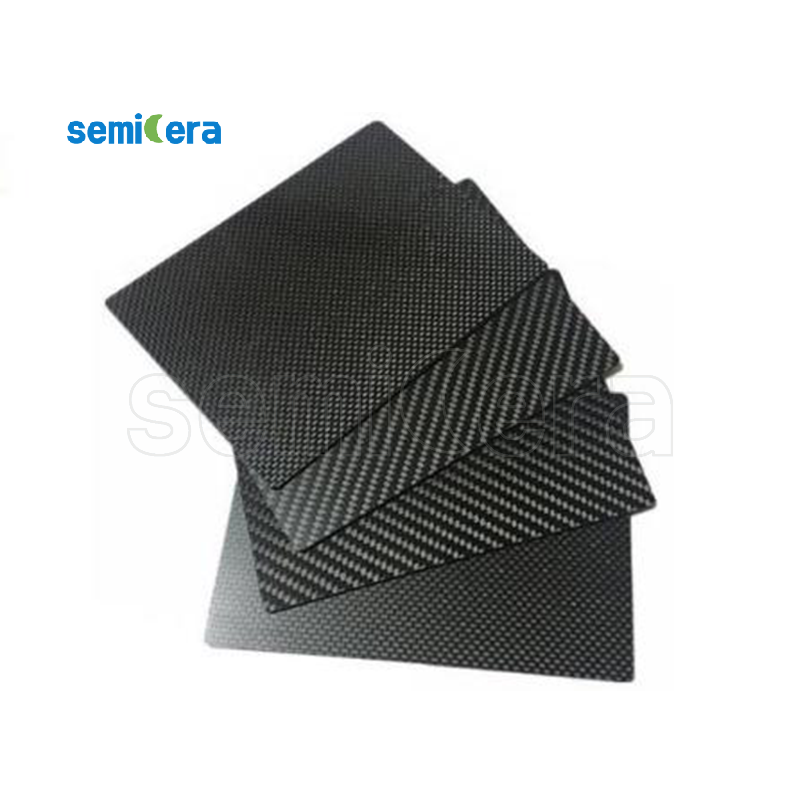

Crafted with cutting-edge technology, the 6-inch LiNbO3 Bonding Wafer ensures minimal contamination, which is crucial for semiconductor production processes that require high levels of purity. Its excellent thermal stability allows it to withstand elevated temperatures without compromising structural integrity, making it a reliable choice for high-temperature bonding applications. Additionally, the wafer’s outstanding wear resistance ensures that it performs consistently over extended use, providing long-term durability and reducing the need for frequent replacements.